How to Test a Trolling Motor for Continuity

Contents

- Single Phase Motor

- Steps on Testing Single Phase Motor

- #1. General Inspections

- #2. Testing the Earth Continuity and Resistance

- #3. Testing the Power Supply

- #4. Testing the AC Motor Winding Resistance

- #4. Testing the Insulation Resistance

- #5. Testing its Running Amperage

- FAQs

- What are the benefits when you have a single phase motor?

- What are the most prevalent reasons for single-phase motor failure?

- Why is testing an electric motor so important?

- Wrapping Up

Single phase motors are a type of motor that is primarily utilized in homes, stores, offices, and small non-industrial businesses. Like any other electrical component, a single phase motor could unexpectedly malfunction due to various reasons. So, to figure out the actual cause of that problem, it's best to consider testing it with an electrical diagnostic tool like a multimeter, we will go through this below.

In general, there are a few basic steps for testing single phase motor with a multimeter. Those basic steps are the following:

- General Inspections

- Testing the Earth Continuity and Resistance

- Testing the Power Supply

- Testing the AC Motor Winding Resistance

- Testing the Insulation Resistance

- Testing its Running Amperage

Now, a diagnostic tool that is best for this type of testing is a multimeter. In this article, we'll talk about single-phase motors and how to test them using a digital multimeter.

Single Phase Motor

A single phase motor is a rotating machine powered by electricity and can convert electrical energy into mechanical energy. Typically, these are little motors with low torque. Single-phase motors come in a variety of designs. But, what they all have in common is a start winding, a common connection, and a run winding. Also, they cannot produce a rotating magnetic field. Instead, they can only create an alternative field, which necessitates using a capacitor during starting. (1)

Moreover, a single phase motor is commonly utilized in smaller, lower-horsepower equipment and machines, such as one horsepower. Refrigerators, pumps, compressors, fans, and portable drills are among the items that fall under this category. While single phase motors are mechanically simple, that does not mean they are faultless. Due to certain factors, they could run slowly, overheat, or even fail to start on rare occasions. Hence, it's crucial to test it regularly to check your single phase motor's health status and the cause of its failure.

Steps on Testing Single Phase Motor

The main goal of any AC motor test is to identify the motor's health status. So, let's go over how to test a single phase motor with a multimeter? Well, it is simple if you follow a few basic steps. Here are the main steps to go through while determining the health of your motor:

#1. General Inspections

This test is the simplest to complete. As you gain experience handling and working with motors, you will quickly recognize what feels right and when something isn't. So, for the single phase motor, you should do the following:

- Examine the motor's appearance. Check the body and the cooling fan or shaft for any burns or damage.

- Rotate the motor shaft manually to check the bearing condition. If shaft rotation is free and smooth, the bearing is likely in good shape; otherwise, it should be replaced.

- The motor nameplate gives valuable information that can aid in determining the health of the motor. Hence, take a good look at the nameplate.

#2. Testing the Earth Continuity and Resistance

Measure the resistance of the motor frame (body) and earth with your multimeter. A good motor's resistance values should not exceed 0.5 Ohms. Any measurement of more than 0.5 Ohms indicates a defective motor.

#3. Testing the Power Supply

A single-phase motor's predicted voltage levels are 230V or 208V. This level varies depending on utilizing an American or a UK voltage system. So, with your multimeter, you should always check to see if the motor is receiving the proper voltage supply.

#4. Testing the AC Motor Winding Resistance

Using your multimeter, measure the motor winding resistance (ohms). Since a single phase motor has three terminals (S, C, and R), you should measure the winding resistance of the following: C to S, C to R, and S to R.

The measured value of S to R should be equal to C to S + C to R. Now, the following method applies in general to single phase motors:

- S to R – the Ohms reading should be the highest resistance reading.

- C to R – the Ohms reading should be the lowest resistance reading.

- C to S – the ohms reading should be in the middle of the values of S to R and C to R.

Any discrepancy indicates that the electric motor is either defective or needs repair.

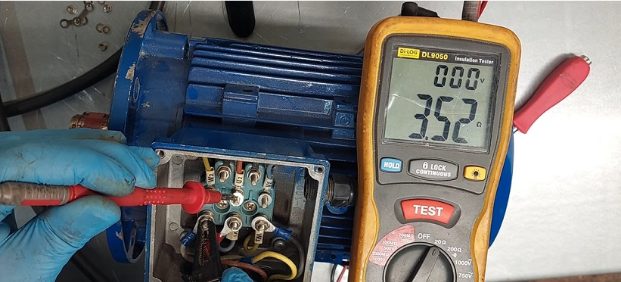

#4. Testing the Insulation Resistance

One of the key symptoms that your motor is malfunctioning is the failure of insulating resistance. Insulation resistance is often measured using a megohmmeter or an insulation tester between the motor winding and the ground.

- Set your insulation resistance tester to 500V and inspect the motor winding's connection to the earth.

- Then, check the phases C to E, S to E, and R to E.

For an electric motor in good condition, its minimum test value is usually 1MΩ.

#5. Testing its Running Amperage

Test the full load amps (FLA) with an appropriate meter or, ideally, a clamp-on meter while the motor is running. Then, compare it to the motor nameplate FLA.

Deviations from the rated FLA may indicate an issue with the tested motor.

FAQs

What are the benefits when you have a single phase motor?

Single-phase motors provide numerous advantages. Single phase motors are less expensive to produce than most other motor types. Single phase motors are often low-maintenance, require few repairs, and are relatively simple to repair. Also, they will last for years, and most single-phase motor failures are due to an improper application rather than a problem in manufacturing the motor itself.

What are the most prevalent reasons for single-phase motor failure?

There could be various explanations for a single-phase motor failing to start, becoming hot, tripping its overcurrent device, or running intermittently. The primary issue could sometimes be found in the power supply, such as the motor controller or branch circuit wire. Other causes could be a driven load jamming or in its thermal switch, centrifugal switch, or capacitor. Also, a burned wire or winding failure, such as a deteriorated bearing or insulation degeneration, could cause issues. They are usually replaced if the motor is more than ten years old and has less than one horsepower. (2)

Why is testing an electric motor so important?

Because electrical defects are frequently the primary cause of motor failure, it's critical to figure out how to fix this issue. You could use various electrical diagnostic equipment, such as a multimeter, to test your single phase motor. It will assist you in determining the root cause of the problem with your motor. It makes it simple to identify and resolve issues that lead to electrical motor failure. When you find an issue with your electrical motor, you will be able to save money and time by preventing unexpected shutdowns.

Wrapping Up

It's tough to visualize the cause of a single-phase electric motor failure. Using a multimeter, however, can help you perform a fast check-out and will assist you in determining the source of the issue. However, you'll need to gather and weigh a lot of data before putting it all into context.

Moreover, electricity will never be required during your single phase motor testing. As a result, before starting your test, make sure the motor is unplugged from the power supply.

Take a look at some of our related articles below.

- How to test blower motor with multimeter

- How to test a capacitor with a multimeter

- How to test spark plug with multimeter

References

(1) magnetic field – https://www.britannica.com/science/magnetic-field

(2) horsepower – https://www.britannica.com/science/horsepower

Video Reference

Source: https://toolsweek.com/how-to-test-a-single-phase-motor-with-a-multimeter/

0 Response to "How to Test a Trolling Motor for Continuity"

Post a Comment